Fully automatic route monitoring through fibre optic sensing

Article: A digital ear on the track

11/2020 – The aim of the fibre optic sensing project conducted by DB Netz AG and DB Systel is to significantly improve the current passenger warning system using fibre optic sensor technology and an AI-based data platform.

“Your attention please on platform 4. Train passing at speed.” Announcements like this are used by Deutsche Bahn to warn passengers when a train is racing past a platform at 160 kilometres per hour. But announcements are also made even when slower passenger trains or freight trains are passing by. What very few rail customers are likely to know is that these warning announcements, which are operated by DB Station&Service, usually involve a lot of complex manual work.

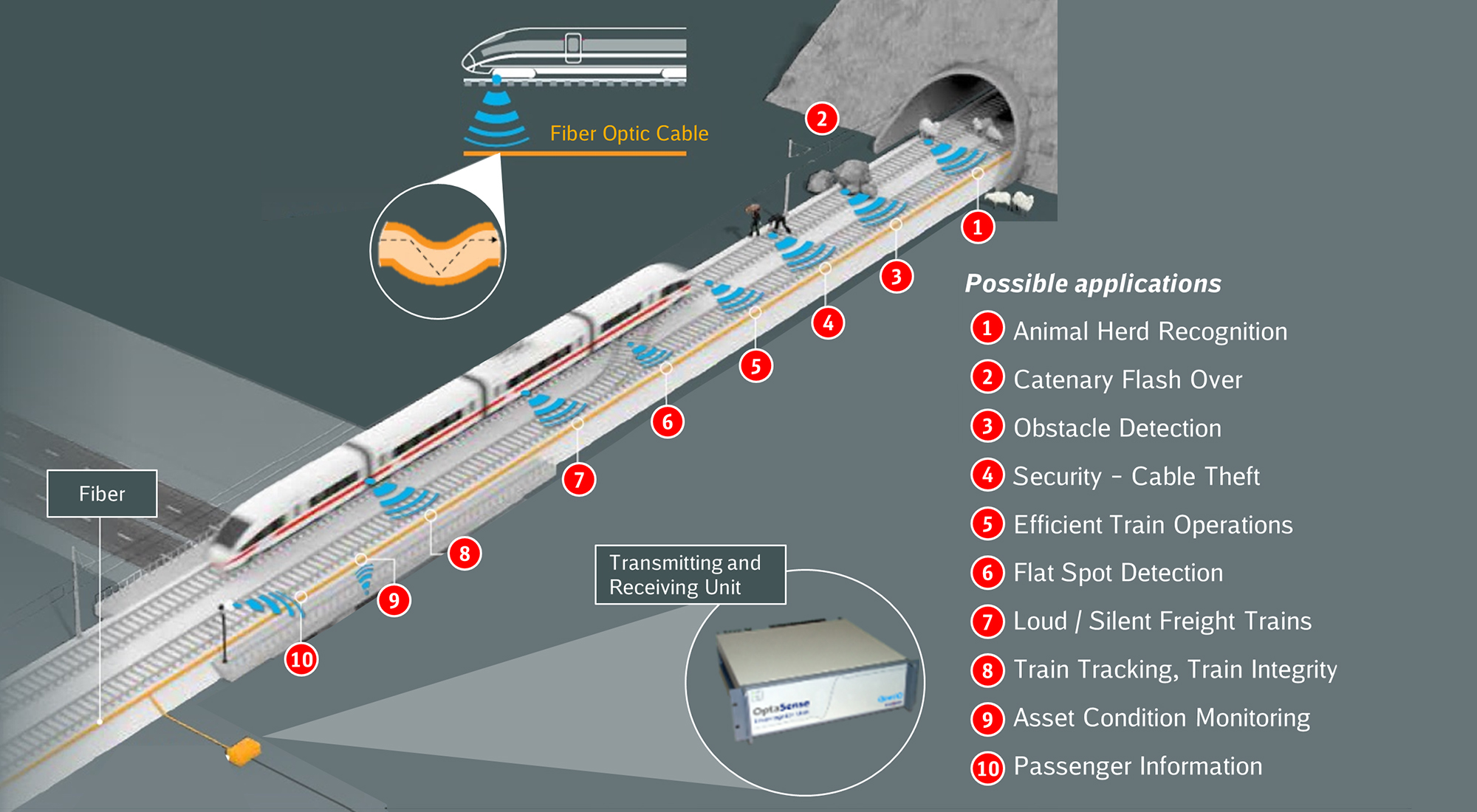

But this is about to change. Fibre optic sensing (FOS), in combination with artificial intelligence and a big data platform, is able to determine exactly where a train is located on a particular line section and when it will reach a station. By combining a sensor system that records the acoustic signals of approaching trains using fibre optics with a big data platform, it is possible to have a fully automated passenger warning system on the station platform.

Making the best use of the existing infrastructure

“At the moment, DB Station&Service AG has to operate warning announcements at around 170 platform edges throughout Germany, regardless of the speed of the train passing by,” says Andy Lämmerhirt of DB Netz AG. He is in charge of the fibre optic sensing (FOS) project, which, together with a team from DB Systel, is optimising the interaction between FOS and a specially designed data platform to determine the safe and ideal timing for these warnings under all working conditions.

“At the moment, DB Station&Service AG has to operate warning announcements at around 170 platform edges throughout Germany, regardless of the speed of the train passing by.

A fully automatic warning system has been in use for years on the Berlin-Hamburg route, with warnings that are triggered by trains driving over switch-on contacts. However, this type of system is more costly and less flexible than a warning system based on fibre optic sensing. With an FOS box, it is possible to monitor all platform edges over a distance of up to 100 km with just one sensor system.

The FOS technology can make use of some 14,000 kilometres of optical fibres along the railway lines in Germany in the form of railway telecommunication cables laid in concrete troughs next to the track. “Among other things, they are used for communication between signal boxes,” says Andreas Freese from DB Systel, who is involved in the FOS project as a product owner.

2,500 light pulses per second

These telecommunication cables have considerable reserve capacity. “Not all of the 24 to 144 fibres per cable are in use,” adds Andy Lämmerhirt. Any unused fibres can be utilised for fibre optic sensing. Just one free fibre is sufficient to convert the fibre optic cable into a kind of virtual microphone. The individual FOS sensor systems provided by the manufacturers are installed in the signal boxes at intervals of around 40 to 80 km. They consist of a transmitting and receiving unit, an analysis unit and an input unit.

The optical time domain reflectometry method is used to detect events. With this method, the transmitter and receiver unit sends laser pulses through the optical fibre and detects the reflected scattered light. Up to 2,500 light pulses per second are transmitted into the fibre. If, for example, a train travels along the monitored route, it generates vibrations, which spread to the optical fibre in the cable trough next to the line. The reflections in the cable, which are caused by micro-bending, can be measured and also used to identify the cause of the reflection. “Every event triggers a characteristic vibration pattern. We analyse the pattern – its frequency and amplitude – and an algorithm can learn to recognise these patterns,” explains Andy Lämmerhirt. The data collected is analysed for known patterns – in near real time and accurate to within 10 metres. A single transmitter and receiver unit can optically scan up to 100 kilometres of line.

99 percent certainty

With fibre optic sensing, every train journey can be completely monitored. “We can always find out where the train is and how fast it’s going,” says Daniel Pöppelmann, who as lead architect for the FOS project is responsible for integrating the data on the big data platform. “The AI recognises the train and tracks its progress and the information is fed into the data platform via an interface.”

"We can always find out where the train is and how fast it’s going."

The accuracy of the measurement of a train arrival at a virtual station on a high-speed line between Würzburg and Fulda by means of FOS has already been determined as part of a feasibility study. It is 99 percent, which far exceeds the requirements. After completion of the first test phase, FOS is now to be examined for initial operational usability in the form of a passenger warning system. To this end, the proof of concept, i.e. the examination of the basic feasibility of the project, will be carried out by the end of the year. “After that, we plan to subject the system to a practical test lasting several months on a section of the line from Berlin to Dresden. We want to make the algorithm that recognises the trains even more robust,” says Lämmerhirt. The FOS system is already able to detect trains and their speeds in all weathers. It can also distinguish the running noise of an ICE train from the noise emissions of nearby temporary construction sites. “But there is still room for improvement,” says Lämmerhirt.

All data from a single source

“Of course, a further challenge is to integrate the various data sources from the DB Group,” adds Pöppelmann. “They have grown historically, which explains why infrastructure works with completely different data structures than train scheduling. This makes it difficult to recognise which train we see as a FOS event and where it’s going.” But Pöppelmann is optimistic that it will be possible to dovetail the FOS data with Group data from operations and infrastructure. “We have great support from all levels of the company and we have all the skills we need in the proof-of-concept team,” says Pöppelmann.

The innovation potential of fibre optic sensing is hard to overestimate. Deutsche Bahn is opening up a completely new source of information. This will not only have advantages for rail passengers, who in future will receive more accurate and consistent warnings about trains passing. “FOS makes entirely new applications with massive benefits for the rail infrastructure possible,” says Pöppelmann. Through distributed acoustic sensing, for example, the system is able to detect flat areas on wheels. Great progress has already been made in identifying noises that indicate cable theft – which in turn could help to reduce train cancellations or delays. By combining a multifunctional sensor system and integrated data platform, the fibre optic sensing project thus ensures a better overview and greater safety – not only on platforms, but also on the rails.