Digital Freight Transport

Article: How the DB Modular Cloud became digital support for transshipment terminals

When a container needs to “transfer” between truck and rail, that is DUSS’s specialty. This is the “Deutsche Umschlaggesellschaft Schiene-Straße.” As a subsidiary of DB InfraGO, DUSS and its terminals specialize in this loading of goods: “We move loading units from the truck to rail and back again; we really get goods onto the rails,” explains Katrin Altmann, who is responsible at DUSS for the “BLU” operations control system. At more than 20 transshipment terminals, the company transfers over two million so-called “loading units” every year. These are primarily shipping containers or semi-trailers that complete part of their journey in a climate-friendly way on a freight train.

The digitalization of transshipment terminals

Even in this heavy-duty world between freight trains, container cranes, and trucks, digitalization now plays a very large role in making processes faster and simpler: “When a truck used to enter our terminals, it was as if it had suddenly appeared out of nowhere,” Katrin Altmann recalls of long-ago practice. “It would pull into a so-called pre-staging area at a check-in bay and wait until an operator arrived with a form and inspected the loading unit.” These staff members recorded the truck and loading unit and documented any visible external damage to the cargo.

Every day, hundreds of trucks enter and leave each of these terminals, all of which must be checked and coordinated. Naturally, only trucks with a valid order should be allowed onto the premises. Once that is clarified, the trucks must be guided to the right crane position at the right time. Planning and order management at the terminal has long since been digitalized; even the staff’s old clipboards were replaced by tablets years ago. Today, freight forwarders use a smartphone app from DUSS, for example, to register a time slot for ‘transhipment’ here. The operations control system manages all tasks in the terminal behind the scenes, plans loading onto the trains, and manages storage positions. The system mediates between the operators involved and the numerous freight forwarders.

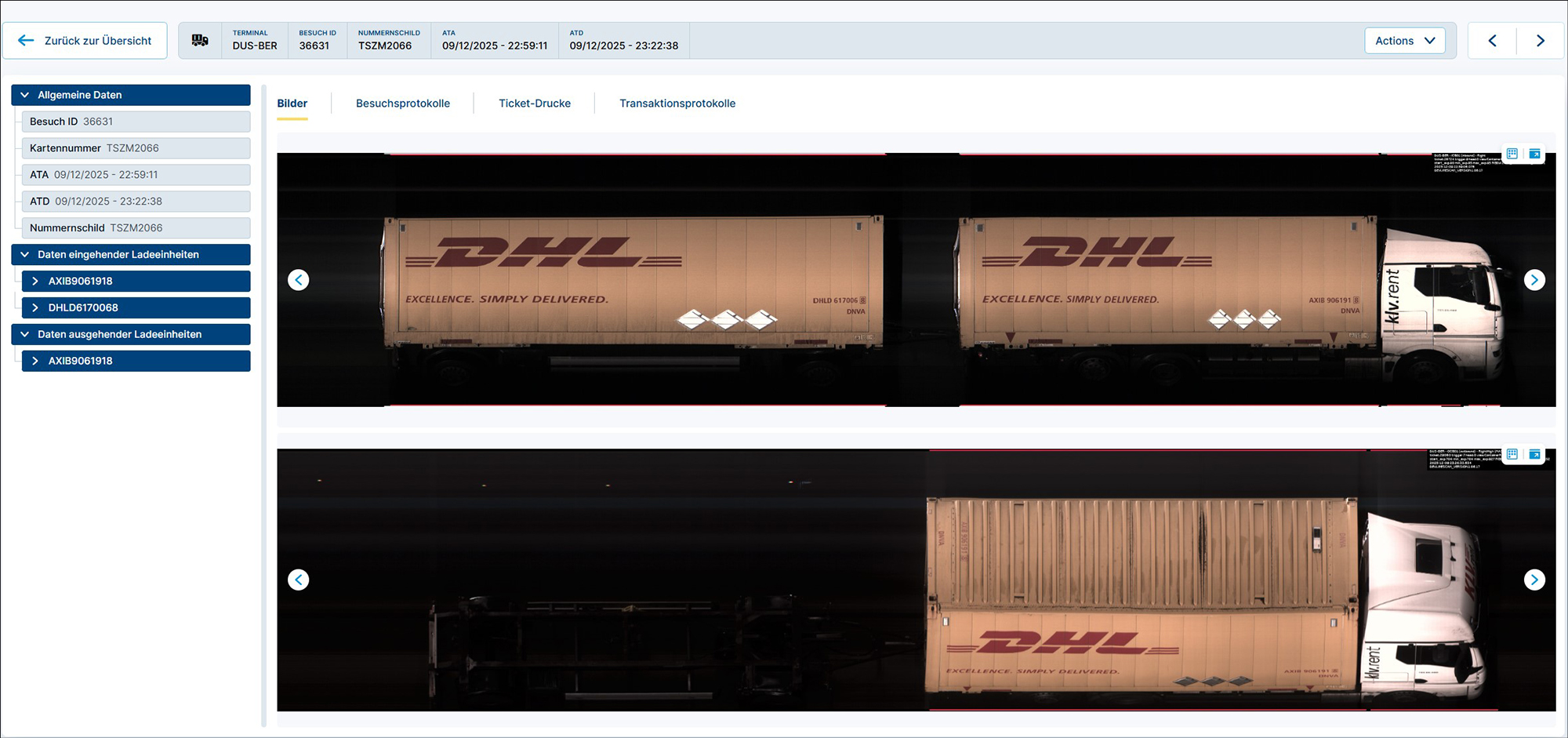

Automated video gates as the truck doorkeeper

Today, at many DUSS loading terminals, smart video gates recognize both the truck by its license plate and its load upon entry and exit: “A truck wants to enter; the camera recognition sends a query to our system: Is this truck allowed to enter the terminal? If yes, the barrier opens,” explains Katrin Altmann. “If not, the barrier stays down and a staff member at the counter receives a message from the system: someone is at the barrier, but there is no authorization,” says the person responsible for the operations control system. The camera gates offer additional advantages for terminal operations: “We now have a pictorial data record: How did the truck enter? When did it enter? What was it carrying?” Katrin Altmann explains. The recordings also help document any potential damage. Thanks to the video verification, the robust shipping containers no longer need to be manually inspected before loading.

This saves trips and effort for on-site staff. Employees only need to check the truck in person in cases requiring clarification. This can happen if the license plate does not match the order - for example, if the truck was swapped at short notice by the carrier - or if the camera system did not clearly recognize something: “Once clarified, the data record is corrected and entry is approved.” Trucks that have registered digitally in advance via the smartphone app can, in most cases, drive directly into the lane for the crane. This automation saves a great deal of time during processing and significantly reduces both the space required and the waiting time for trucks on site.

At exit, camera gates again digitally verify whether the truck and load belong together: “That is a very big part of our security,” says Katrin Altmann. “It records which truck is taking which loading units. Our system compares: for example, the truck has two containers on board; if that is permitted, the barrier opens. If not, the barrier remains closed.” An order is then automatically created for staff in the system, and the truck must be checked again in person. “In the past, for example at the Munich site, there was always a staff member at the barrier on every shift who checked whether each truck was allowed to exit. So that was a major step forward in digitalization for us,” Katrin Altmann recalls. “We have eliminated many manual inspection processes.”

Into the cloud in just a few days

DUSS now uses the DB Modular Cloud as the infrastructure for the software of these video systems. The solution controls on-site truck processes and can also analyze them. Originally, DUSS operated the software for each individual transshipment terminal on local clients. However, this local installation had the disadvantage that external access was cumbersome. For example, staff in the damage department had to laboriously log into the respective local networks via VPN to gather the necessary information during investigations. Together with the supplier of the video gates, the idea emerged to move the camera systems’ backend centrally into the cloud.

“We are a group company, and I find it convenient to have a solution from a trusted hand within the Group rather than searching for an external solution on the market.”

Through the existing collaboration with DB Systel’s IoTSec team, which was already involved in the project for IT security, contact was made with the DB Modular Cloud team. “I always prefer to have an integrated solution from within the Group rather than something external,” says Katrin Altmann. The Modular Cloud is a flexible cloud infrastructure based on AWS, where any business unit within the railway can easily order fully DB-compliant cloud resources: “Just fill out a PDF, and it takes us half an hour to provision the infrastructure,” reports Moritz Bertram, who supported Katrin Altmann as part of DB Systel’s cloud team during the move to the cloud.

Into the cloud in a few steps

“And then we got started,” Katrin Altmann recalls. “First it was about permissions: how does the service provider get access? This is where the ‘Secure Remote Maintenance’ product is now being used for secure access to the systems. Access to the system is only possible after prior approval.” Together, configurations for rights and access were set up correctly: “The Modular Cloud operates according to the principle of shared responsibility,” reports Moritz Bertram. “That means we deliver everything up to the operating system. We take care of it and apply patches so everything is always up to date. As soon as it moves to the application level, the customer is responsible.” In this case, DB Systel took care of finishing the infrastructure configuration so that the video gate supplier could install its software and interfaces for cloud operation. From the initial idea to go-live, including the supplier’s adjustments, the process took around six months.

Each new site can now be added to the cloud platform in a short time. Katrin Altmann is not an IT specialist and, thanks to the collaboration so far, already has a routine for onboarding a new site to the cloud: “It’s built in a standardized way and is like plug-and-play: I order a VPN tunnel, request my firewall rules, add one more rule in the AWS catalog, and the new site is up in two days. Nothing needs to be changed at the interface anymore.”

Cloud migration made easy

“We’re absolutely happy to be working with this. We now have a centralized view,” says Katrin Altmann. “Because the software is in the Modular Cloud, everyone who deals with these sites - our headquarters, our managing directors - can access it. Previously, this was somewhat more complex due to ‘network hopping’.” Moritz Bertram adds: “Users can also change the server’s performance at any time if capacity is tight or if the server is underutilized. So you are very flexible, and no downtime occurs.” Katrin Altmann uses this, for example, for a test environment. “Now that many here are very enthusiastic about it, we’re looking at what else we could move into the Modular Cloud,” Katrin Altmann concludes. “For everything that is suitable, I would like to do that. We have secure 24/7 operations within DB and a very transparent cost breakdown.”