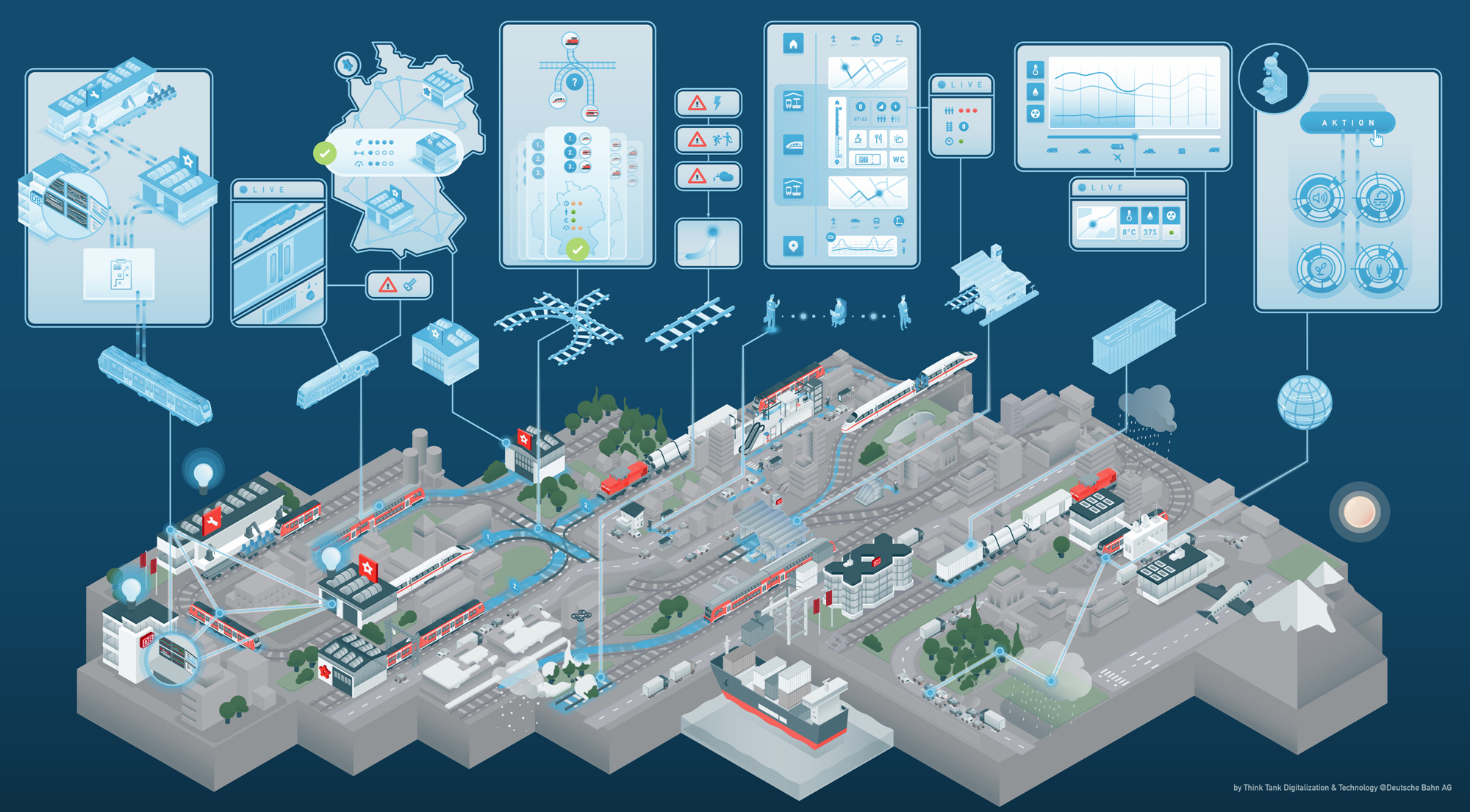

IoT platform

Article: The online meeting place for digital device data

01/2022 - At Deutsche Bahn, the Internet of Things is gaining more and more momentum. Whether it's about sensors on trains or networked technology in stations or along the route: in future, it will be possible to collect recorded data, analyse it and use it to improve the passenger and user experience via the Group-wide IoT platform.

Deutsche Bahn has consistently focused on digitalising its value chain for years now – and this is one journey that is far from over. The aim is to improve existing processes in terms of their cost structure and quality, but also to meet changing needs and user behaviour with new digital services. The current production system needs to be optimised to make our own processes more efficient, faster and more cost-effective; for example, by putting more trains on the same route. At the same time, the railway must be innovative, attractive and offer passengers and customers new services – such as electronic ways of ordering food and drinks directly to your seat on the ICE or methods of tracking consignments in freight transport. The key to all this is better information about individual assets – something which the DB Group has an awful lot of.

Assets within the DB Group

- Over 2,600 signal boxes

- A good 65,500 points

- Around 5,400 stations with displays, clocks, lifts and escalators

- Around 8,500 locomotives, ICEs and multiple units

- Over 78,000 freight wagons in the cargo sector

- Numerous maintenance depots

(Data according to Group presentation 09/2021)

However: "In many areas we don't even know exactly what our production system is doing in detail. When a production asset in a maintenance depot or a vehicle fails, it is often already too late for a suitable countermeasure," explains Alexander Richter, Product Owner Internet of Things (IoT) at DB Systel. "We can catch unexpected failures or behaviours earlier and treat them better by using IoT to record and understand what is actually going on with our assets."

Predictive analysis option

Since July 2021, all this has been possible thanks to DB Systel's IoT platform. This is where all the data generated by sensors and other collection methods is prepared, processed, coherently analysed and usefully integrated into specialised applications. The actual values provide information about what is happening right now. "We can look at the present time and see how the asset is doing at that exact moment," says Alexander Richter. "But we can also look into the asset and determine its state of health based on its operational data, which allows us to make predictions for the future. This is called predictive analysis: if the situation continues like this, this specific thing will happen. And we then respond to that forecast, as a precaution." In the best-case scenario, an action will be triggered automatically in the event of an anomaly, which then mitigates and prevents the potential problem from developing.

From technology procurement to connectivity, recording and processing data to running analyses and translating the results into the relevant processes: to make use of IoT, a long chain of information has to be created before anything at all can be controlled. This is quite demanding, complex and expensive work. "If people want to solve technical problems, they should concentrate on the real technical benefit without having to worry about everything else," says Alexander Richter. With the central IoT platform, users from different business units receive a toolbox that is full to the brim of digital tools provided by DB Systel. "You don't have to be an expert in IT or security to put a technical solution into practice, because the digital tools on this platform are hardened and safe to use," explains Alexander Richter. He goes on to summarise the core message of the platform strategy thus: "Anyone using these tools can be confident that they will work as they should."

"Participation is rewarded"

To make sure this is the case, the platforms rely on state-of-the-art cloud technology, for example from AWS (Amazon Web Services) and Microsoft. The speed of innovation at the world's largest IT companies cannot be beaten, with major partners providing several hundred new features every day. The trick is to be smart in juggling the cloud partners' different service portfolios. "We must remain flexible and open to innovation. We examine the service portfolio, select exactly what we need to meet DB's current digitalisation needs, then make those features available in such a way that they can be used securely and as easily as possible within the railway sector. We need to ensure that IT can be even more actively shaped by people who are not IT professionals." The aim is clear: to work more and more often with the tools that already exist, so that people do not try to reinvent everything themselves. "We make sure that our digital services are sufficiently hardened so they can function securely and reliably," continues Alexander Richter. Behind these services are Deutsche Bahn's Group partners, who are empowered to shape them as they see fit. And the more these services are taken up, the better they become for everyone. But all users benefit from a technological point of view too. "When users get involved and formulate their requirements for the platform, the services are tailored to them even more. Participation is rewarded."

DB Fernverkehr AG, one of the first partners involved in the IoT platform, has also recognised this fact. "Based on comprehensive data available in real time, we consistently and effectively align our business with what passengers actually need. Our data experts combine various perspectives – those of passengers, but also vehicles, depots and staff – on the current operational and traffic situation; they prepare for decisions; and they identify control levers that can be operated to make further improvements," says Sönke Schmidt, Head of Data & Productivity Solutions at DB Fernverkehr AG. The IoT platform is an important building block here and forms the basis for a vehicle's digital twin. "We are fully committed to ensuring the IoT Group platform interacts with our Fernverkehr Data Lake (FLake). We are integrating the sensors and telemetry equipment of our ICE fleet into the platform in a way that is secure and standardised to allow for real-time monitoring, for example."

Florian Hoffmann is Product Owner Data Lake at DB Fernverkehr AG. He too is convinced of the new platform's benefits: "For us, the IoT platform is an opportunity to standardise a wide range of different interfaces. As a product owner, I no longer have to worry about handling certificates or having interfaces accepted by security experts, for example. The central system means my application is less complex." In the first step, the comfort IT components of the ICE fleet were integrated into the IoT platform and a system for monitoring the availability and quality of the Wi-Fi service was set up. If routers, access points or other central components are not working properly, this information is sent from the train to the IoT platform. Thanks to the near-time monitoring function in the service monitor, operations management can respond to malfunctions immediately and arrange for them to be remedied as quickly as possible.

But the possibilities of IoT can help all business areas – and in at least two different ways. It can be harnessed to optimise our own existing processes or to create new value propositions for passengers and customers, thus opening up new market potential. For this purpose, the IoT platform offers a collection of managed, ready-to-use elementary platform services and features with which IoT resources and their data can be easily and securely connected, managed and made available for cloud applications of the Deutsche Bahn IT ecosystem. In other words, it is the link for integrating operational assets into digital IT application landscapes and allowing them to interact with each other in both directions. "The goal is to design our production system in such a way that the participants in this network can exchange information with each other autonomously and based on their own particular condition in order to make better decisions. To do this, we need to get closer to the assets and understand them better. IoT is a pioneer in this regard and there is enormous potential for Deutsche Bahn to benefit," says Alexander Richter.